1

/

0

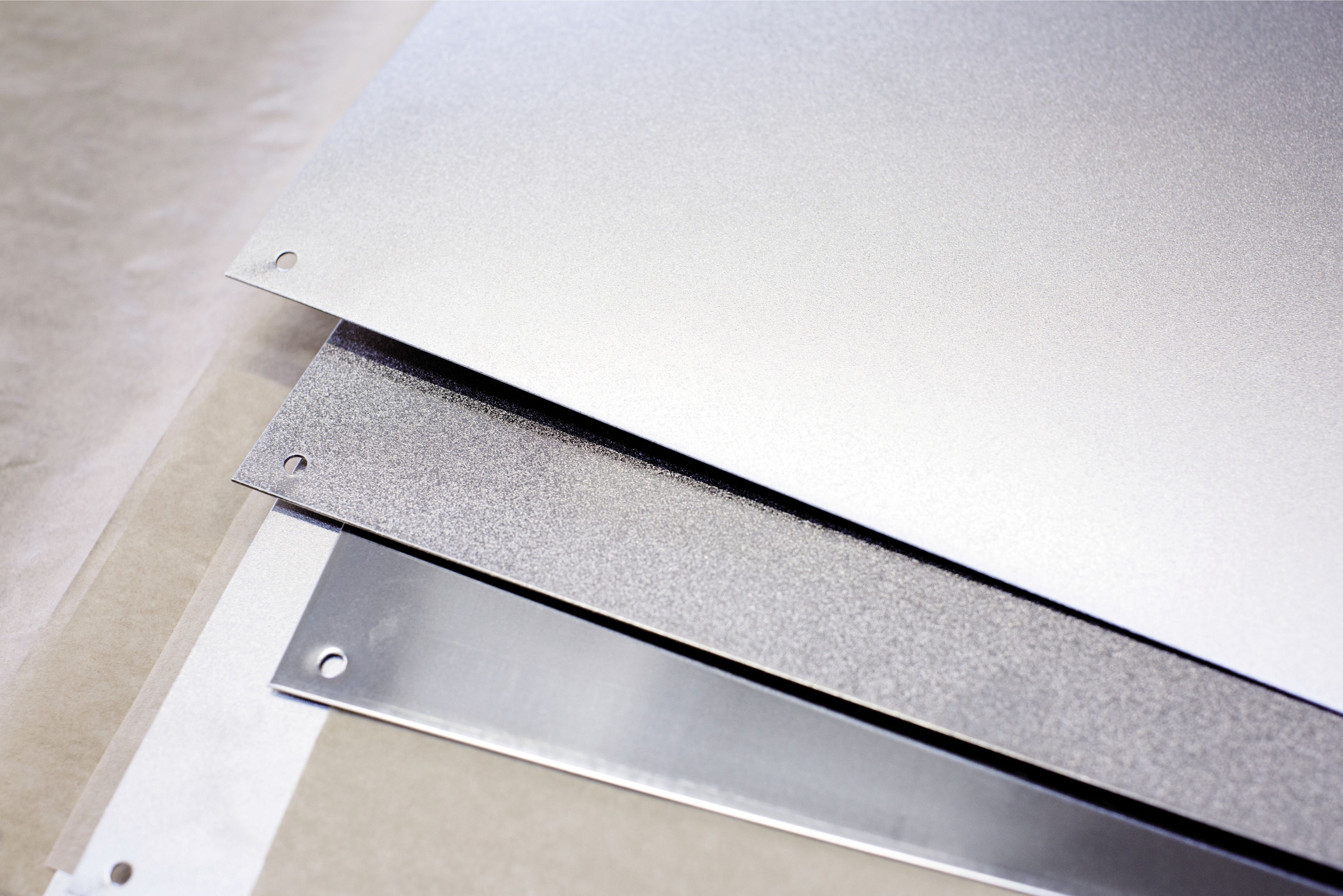

The new stainless steel surface will delight anyone who loves the coolly elegant look of stainless steel and also appreciates a tough and durable surface. Durinox is distinctive for its velvety-matte look and pleasant feel, while also being impervious to scratches and fingerprints. Thanks to its special surface texture, Durinox Stainless steel is easy to clean and care for.

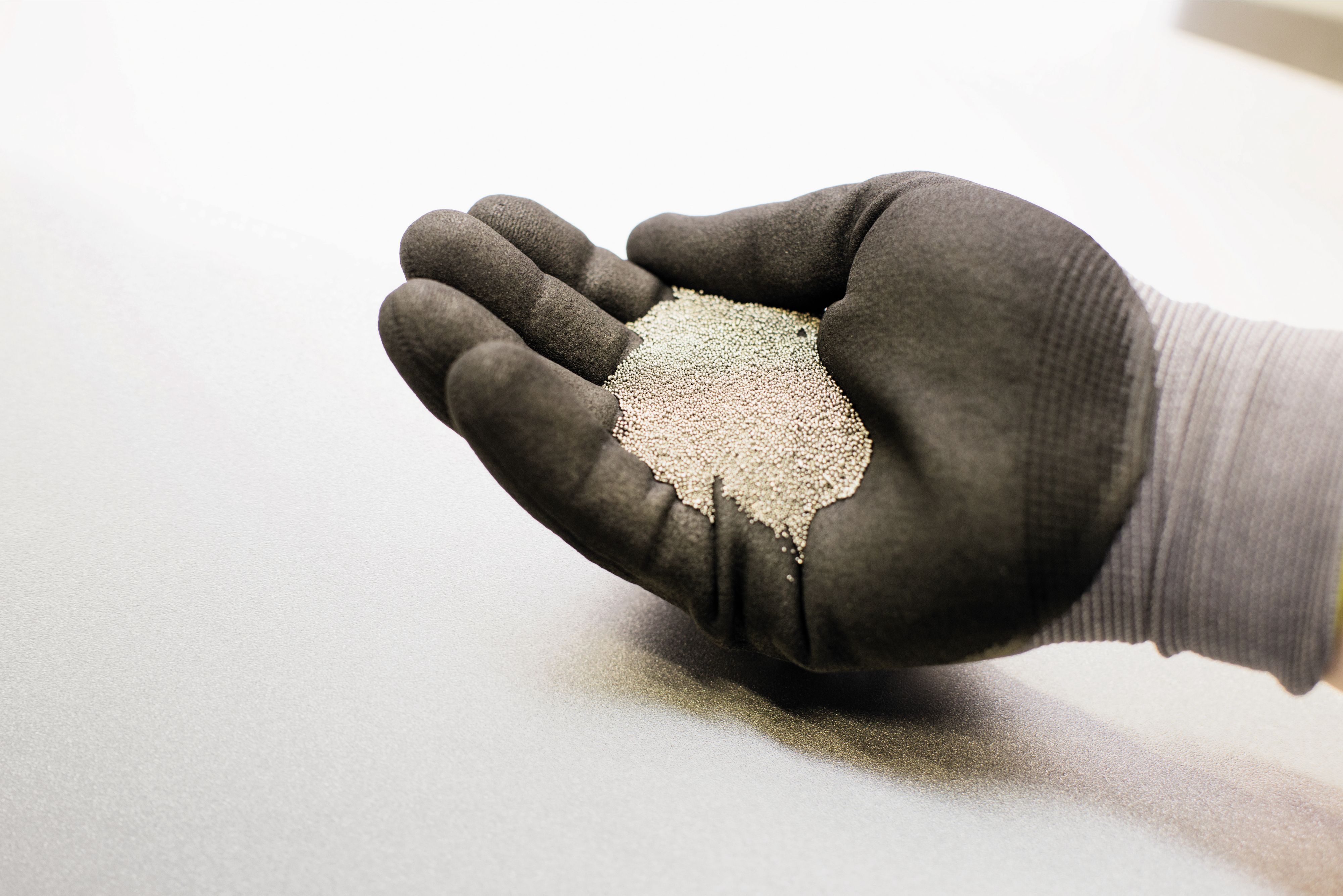

High-speed blasting at over 300 km/h

One surface. Countless designs.

How is the Durinox surface actually manufactured?

Pure stainless steel